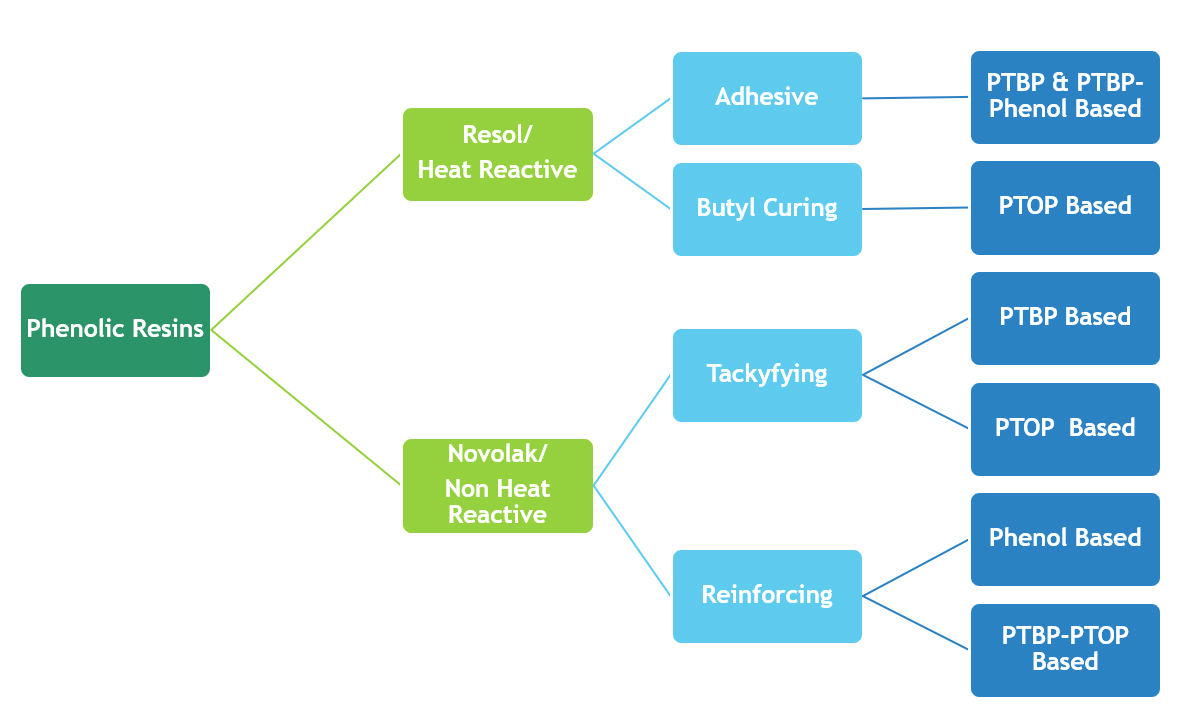

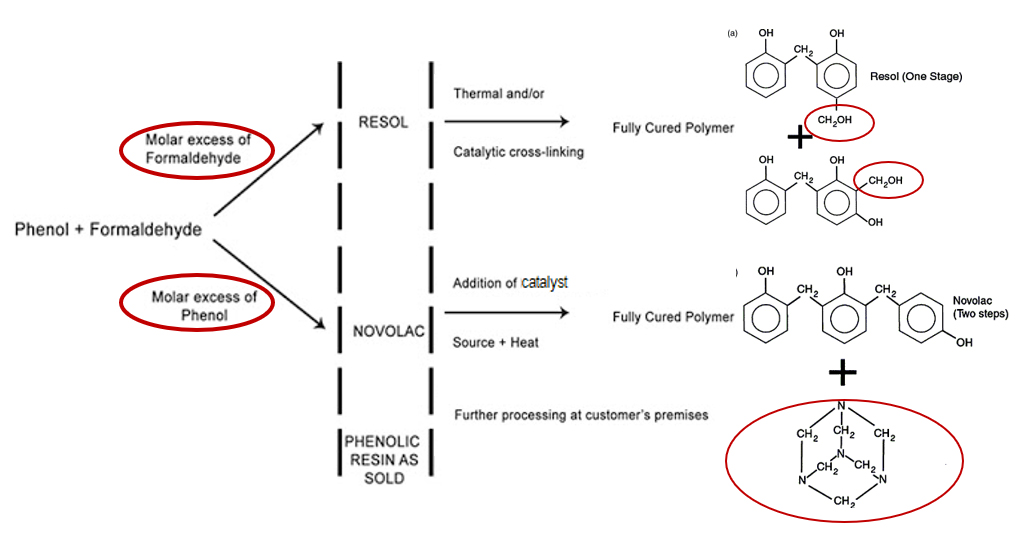

Application of Alkyl Phenolic Resins (Novolaks) Difference between RESOL

Difference between RESOL & NOVOLAC.

Alkyl Phenolic Resin/PTOP Novolak

| Rubber Goods(Tackifier | Tacky/Adhesive Tape | Inks |

|---|---|---|

| Tire/Tyre | Masking Tape | As Tackifier |

| Conveyor Belts | Fabric Tape | |

| Hose | Synthetic Tape | |

| Rubber Coated Fabric | ||

| Mechanical Goods |

Alkyl Phenolic Resin/PTBP Novolak

| Rubber Goods (Tackifier) | Tacky/Adhesive Tape | Inks |

|---|---|---|

| Tire/Tyre | Masking Tape | Coil Coating |

| Conveyor Belts | Fabric Tape | Wire Enamel |

| Hose | Synthetic Tape | Protective Coating |

| Rubber Coated Fabric | Marine Coating | |

| Mechanical Goods | Insulation Vanish |

Alkyl Phenolic Resin/ Novola/Tackifier

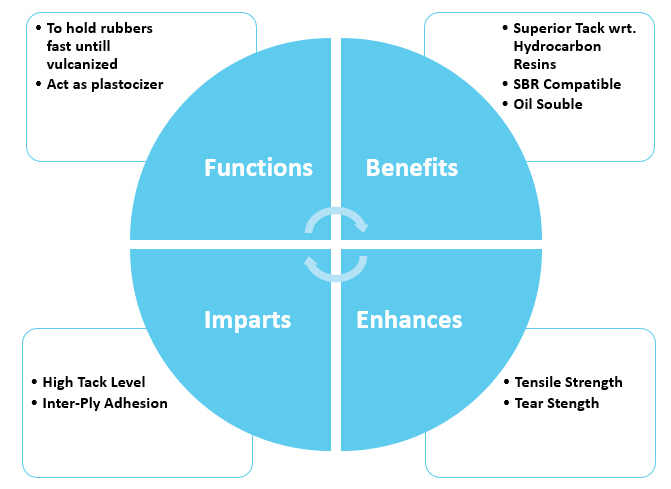

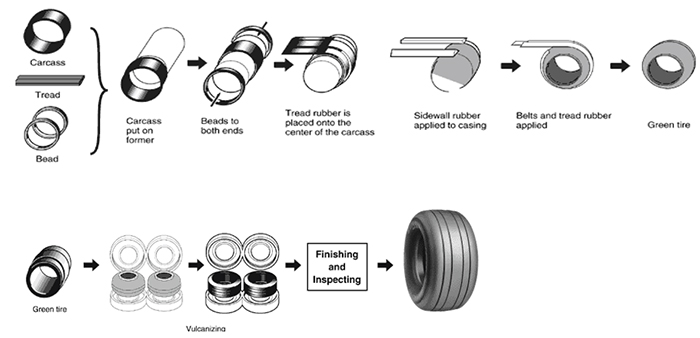

Layers of Rubber need to be “held” in place before “curing”

Tackifier Resins impart “tack” to build these layers

Chemical Bond Formation

Occur during vulcaniztion

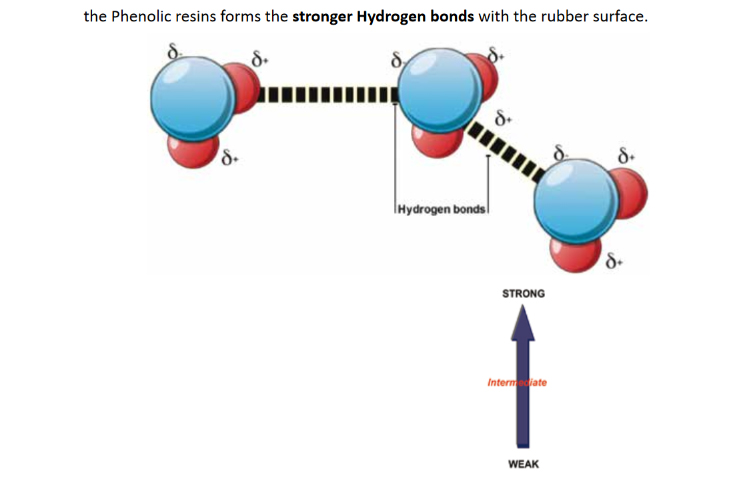

Hydrogen Bonding

Formend by Phenolic resin tackifiers

Van der Waals Forces

Weak intermolecular attraction improved by all tackifiers resins

| ALKYL PHENOL RESINS / TACKIFIER / TACKIFYING/INSULATING/PTBP | |||

|---|---|---|---|

| POLYTONE® AP 120 | POLYTONE® AP 120 H | POLYTONE® AP 120 E | |

| Colour | Pale Yellow/Light Reddish Brown | Pale Yellow/Light Reddish Brown | Light Reddish Brown |

| Colour Gardner (60% Soln in Xylene) | 8 Max | 8 Max | 12 Max |

| Softening Point (Ball & Ring) | 92 – 103 °C | 98 – 110 °C | 135 – 145 °C |

| Acid Value | 42 mg KOH/ g resin (Max) | 60 mg KOH/ g resin (Max) | 85 mg KOH/ g resin (Max) |

| ALKYL PHENOL RESINS / TACKIFIER / TACKIFYING/PTOP | ||

|---|---|---|

| POLYTONE® AP 121 | POLYTONE® AP 121 H | |

| Colour | Pale Amber | Pale Amber |

| Softening Point (Ball & Ring) | 85 – 95 °C | 92 – 104 °C |

| Acid Value | 42 mg KOH/ g resin (Max) | 42 mg KOH/ g resin (Max) |

| Free Phenol | 1.0 % Max | 1.0 % Max |

- Industry Leader & Standard: SI Group/SCHENECTADY (SP 1068)

- Other Players: Sumitomo Bakelite, Arakawa, Kolon

- Indian Players: SI Group

- Major Consumer : Tire, Tire Remolding Compound Maker

- Other Products used in this application

- Hydrocarbon Resin

- Petroleum Resin

- C9 Resin

| Rubber Goods (Reinforcing) | Mounding Compounds | Abrasives |

|---|---|---|

| Tire/Tyre | Foundry | Cutting Wheels |

| Conveyor Belts | Switch Gears | |

| Hose | ||

| Rubber Coated Fabric | ||

| Mechanical Goods |

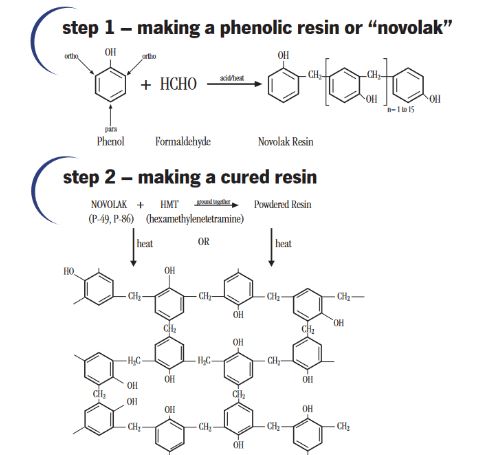

Alkyl Phenolic Resin/Reinforcing

- These resin in presence of catalyst become “Thermoset”.

- They provide “plasticizing effect” while processing.

- They increase “Shore Hardness” of Rubber Compound.

- They provide Hardness, Chip Resistance, Abrasion Resistance.