POLYTONE®

Butyl Curing Resin

About POLYTONE® AP Series – Vulcanising Resin

With more than 35 years of experience, and more than 30 Grades in POLYTONE™ AP Series, we offer resins to a wide spectrum of Industries.

POLYTONE AP 113 and AP 113 A are heat reactive octylphenol-formaldehye resins that contains methylol groups. Its formulated for the cure system of Butyl (Isobutylele-Isoprene) rubber by resin curing system.

Compatibility with other elastomers is good due to the presence of octyl group and can be used to make cements with wide range of properties. It can also be used to formulate pressure sensitive adhesives, Inks and thermoplastic elastomers. The reactive methylol groups offers “functional sites” for various reactions like with rosin in printing inks.

The reactive methylol groups offers “functional sites” for various reactions like with rosin in printing inks. POLYTONE AP 113 and AP 113A can also be used in in manufacture of solvent based adhesives.

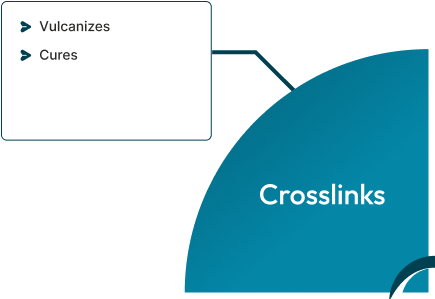

Type

Heat Reactive

Thermoreactive

Thermosetting

Crosslinking

Vulcanising

Chemistry

Alkylphenol Formaldehye

Para Octyl Phenol - Formaldehye

PTOP Resin

Phenolic Resin Type

Resol

Butyl Curing Resin/Octyl Phenol Based Resin

| POLYTONE® AP 113 | POLYTONE® AP 113A | |

|---|---|---|

| Chemical Classification Form | Octyl Phenol (PtOP) Formaldehyde Resol Resin | Octyl Phenol (PtOP) Formaldehyde Resol Resin |

| Type | Heat Reactive/Vulcanizing/Curing Thermosetting | Heat Reactive/Vulcanizing/Curing Thermosetting |

| Colour | Pale Yellow | Pale Yellow |

| Softening Point (Ball & Ring) | 72 – 80 °C | 72 – 90 °C |

| Methylol Content | 08 – 11 % | 08 – 11 % |

| Moisture Content | ≤ 0.5 % | ≤ 0.5 % |

| Characteristics |

|

|

| Solubility | Soluble in aromatic solvents including toluene, benzene, ketones, chlorinated hydrocarbons, ketones, higher alcohols and naphthas | |

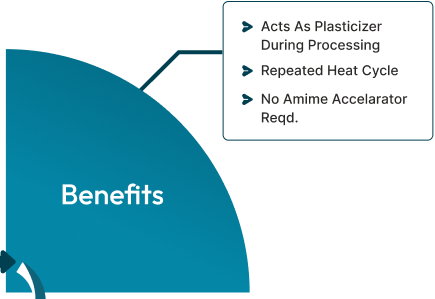

| Benefits | Provides rapid curing at normal curing temperatures and also accelerates cure at lower temperatures. The long chain of this alkyl phenolic resin provides good compatibility with butyl, natural, nitrile, polychloroprene, EPDM | |

| Application/Industry | Tyre/Tire Building, Conveyer Belting, Rubber Hose Manufacture, Rubber Lining, Rubber Adhesives and many more | |

| Why Use Alkyl Phenolic? | How? |

|---|---|

| Curing of Butyl Rubber | Methylol (Reactive Group) cross links along with Rubber to improve rigidity, durability, harness, reduce air permeability |

| In Rubber Adhesive | Provided Tack, Flexing Property, Curing, Adhesion Rare as PTOP Resins are expesive |

| In Tapes | Provide Initial Tack for application |

Butyl Curing Resin Product Information

| SOLUBILITY | |

|---|---|

| POLYTONE® AP 113/A | |

| Alcohols | |

| Higher Alcohols | |

| Ketones MEK | |

| Esters | |

| Aromatic Hydrocarbons Toluene | |

| Aliphatic Hydrocarbons | |

| Naphthas | |

| Water | |

|

Soluble Limited Solublility Insoluble |

|

| COMPATIBILITY | |

|---|---|

| POLYTONE® AP 113/A | |

| Butyl Rubber | |

| Halogenated Butyl Rubber | |

| Natural Rubber | |

| NBR | |

| BR Brominated Rubber | |

| EPDM | |

| Chlorinated Rubber | |

| Silicone Rubber | |

|

Fully Compatible Limited Compatible Not Compatible |

|

| Butyl Curing | Rubber Adhesive | Tacky/Adhesive Tape |

|---|---|---|

| Gloves | Shoe Adhesives | Masking Tape |

| Mats/Sheets | Upholstery Adhesive | Fabric Tape |

| Bladder( Medical) | High Heat Adhesive | Synthetic Tape |

| Bladder(Sports) | Car Under hood Adhesive | |

| Tube (Tire) | Furniture Adhesive | |

| Tubeless Tire Liner |

Tyre/Tire Building, Conveyer Belting, Rubber Hose Manufacture, Rubber Lining, Rubber Adhesives and many more

- Available in 25Kg HDPE Line KRAFT Paper Bags with Anti-Static Liner or 25Kg HDPE Bags

- Choice of ISPM 15 Standard Heat Treated/Fumigated Pallets or Plastic Pallets.

- Individual pallets must NOT be double stacked – pastilles/lumps are likely to agglutinate.

- Properties are not affected by agglutination.

- Can be stored up to 12 months at temperatures below 35 °C

Please follow advice and information provided in MSDS. Protective clothing & workplace hygiene measure must be observed at all times.

Detailed MSDS available on request.

Want to Know more!

Get in touch with our experts!!