POLYTONE®

Acetophenone Formaldehyde Resin

About POLYTONE® APF - Series

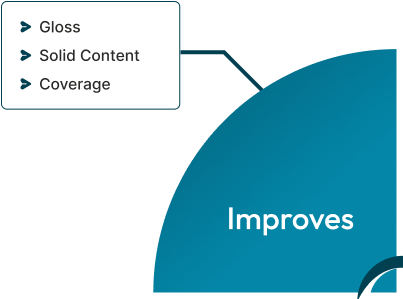

POLYTONE® APF 88 is a neutral, unsaponifiable ketone- aldehyde condensation resin. It is in general used in combination with other binders. Because of its wide compatibility and its efficiency, it is used to improve gloss, solid content and covering capacity in the most diverse paints systems. These resins are highly effective in imparting gloss, adhesiveness, levelling and in increasing the solid content leading to a reduction in the VOC.

Use of POLYTONE® APF 88 increases drying speed and builds resistance to mineral oil.

It is generally used in combination with other binders. As its widely compatible and efficient, its used to improve gloss, solid content & covering capacity of most diverse paint and coating systems.

It also has great viscosity reduction and increase of solids content for industrial coatings, wood and furniture coatings, architectural coatings, and leather coatings.

Type

Polyketone

Ketone Aromatic Aliphatic

Aldehyde Resin

Chemistry

Acetophenone Aldehyde

Acetophenone Formaldehyde

Ketone Aldehyde Condensation

Aromatic Aliphatic Ketone Aldehyde Resin

| POLYTONE® APF 88 | |

|---|---|

| Physical Form | Granules or Lumps |

| Softening Point (Ball & Ring Method) | 88 – 102 °C |

| Color (Gardner) | ≤ 4.0 (50% Soln in Ethyl Acetate) |

| Hydroxyl Value (mg KOH/gm Resin) | 5.0 Approx. |

| Acid Value (mg KOH/gm Resin) | ≤ 1.0 |

| Characteristics |

|

-

Wood & Metal Finishes: POLYTONE® APF 88 is suitable for the manufacture of clear a pigmented nitrocellulose wood and metal finishes.

-

Lacquers & Enamels: Because of its favourable price and low colour number, POLYTONE® K 88 forms a good base for the manufacture of bright clear lacquers as well as while enamels. These lacquers are generally characterized by good adhesion.

-

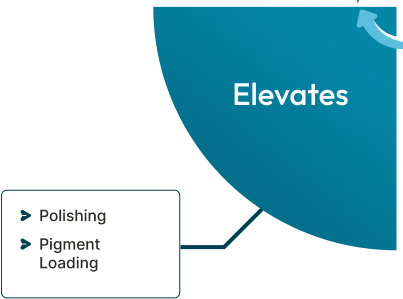

Excellent Gloss: POLYTONE® APF 88 improves the pigment loading capacity of nitrocellulose lacquers so that even at high pigmentation an excellent gloss can still be achieved. In wood primers, POLYTONE® APF 88 nitrocellulose combination lacquers containing 30% (calculated on basis of POLYTONE® APF 88 of maleic resin, coconut oil or ground nut alkyd resin, or a fatty acid alkyd resin, are found to have a rapid solvent release and consequently can already be sanded after a short period of time.

-

Resistance to Mineral Oil: Due to its insolubility in aliphatic hydrocarbons, POLYTONE® APF 88 is suitable for the manufacture of finishes which must be resistant to mineral oil. For the same reason, polishes containing white spirit may also be used on corresponding nitrocellulose polishing lacquers.

-

Good weathering resistance is achieved by combining POLYTONE® APF 88 with nitrocellulose, plasticizers and suitable alkyd resins.

-

Adhesives: POLYTONE® APF 88 acts as a hard resin in combination with soft resins and polychloroprene for the manufacture of adhesive.

- Available in 25Kg HDPE Line KRAFT Paper Bags with Anti-Static Liner/Paper Liner or 25Kg HDPE Bags.

- Choice of ISPM 15 Standard Heat Treated/Fumigated Pallets or Plastic Pallets.

- 500Kg/1000Kg Jumbo Bags available as an option.

- Can be stored up to 12 months at temperatures below 30 °C.

Please follow advice and information provided in MSDS. Protective clothing & workplace hygiene measure must be observed at all times.

Detailed MSDS available on request.

Want to Know more!

Get in touch with our experts!!