POLYTONE®

Phenolic Resin Tackifier

About POLYTONE® AP Series Tackifier

With more than 35 years of experience, and 30+ grades in AP Series we offer resins to a wide spectrum of Industries.

POLYTONE® AP 121 and AP 121 H are our best offering as tackifier resin, these are Octyl Phenol based Novolak Resins which provide superior green tack along with added benefits of low colour and plasticizer properties.

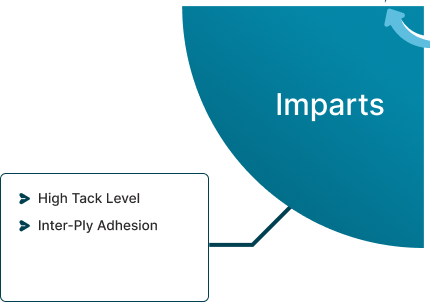

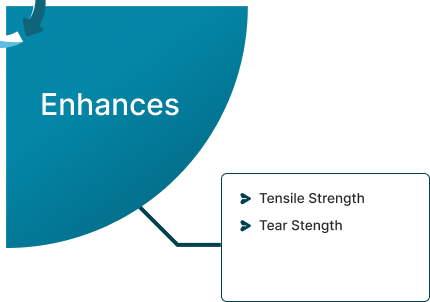

POLYTONE® AP 121 and AP 121 H are designed to develop high tack levels in rubber compounds which are used in tyre construction and mechanical goods. This resin provides tack in elastomers that are usually difficult to tackify. POLYTONE® AP 121 H is used as tackifier in the manufacture of rubber goods such as in tire industry and in the manufacture of mechanical goods.

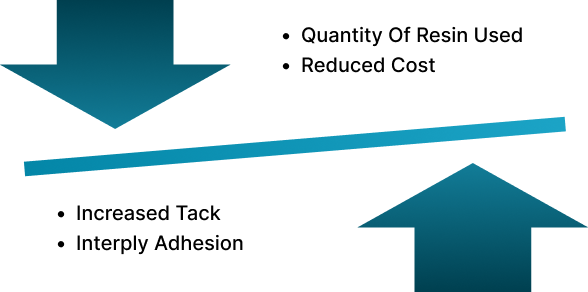

POLYTONE® AP 120 and AP 120 H are Butyl Phenol based Novolak Phenolic Tackifier. They are designed to provide a economical solution to formulators. Though their performance is lower compared to the Octyl Phenol based (POLYTONE® AP 121/121H) products, their cost effectiveness makes them a competitive choice.

They can be readily used to replace Hydrocarbon Resin in the formulation.

Type

Non Heat Reactive

Thermoplastic

Thermosetting

Tackfying

Increases Tack

Chemistry : POLYTONE® AP 120/AP 120H/AP 120 E

Alkyl Phenol Formaldehyde

PtBP Resin

Para Tert Butyl Phenol Resin

Chemistry : POLYTONE® AP 121/AP 121 H

Alkylphenol Formaldehye

POP Resin

PtOP Resin

Octyl Phenol

Phenolic Resin Type

Novolak

Non Heat Reactive

Properties

| Product Name POLYTONE® | Thermoplastic | Non Heat Reactive | Butyl Phenol Based (PtBP) | Octyl Phenol Based(PtOP) |

|---|---|---|---|---|

| AP 120 | ✔ | ✔ | ✔ | |

| AP 120 H | ✔ | ✔ | ✔ | |

| AP 120 E | ✔ | ✔ | ✔ | |

| AP 1201 E | ✔ | ✔ | ✔ | |

| AP 121 | ✔ | ✔ | ✔ | |

| AP 121 H | ✔ | ✔ | ✔ |

| POLYTONE® | Butyl Curing | Tackifier | Reinforcing | |

|---|---|---|---|---|

| AP 113 | PtOP Resol | ✔ | ||

| AP 113 A | PtOP Resol | ✔ | ||

| AP 120 | PtBP Novolak | ✔ | ||

| AP 120 H | PtBP Novolak | ✔ | ||

| AP 120 E | PtBP Novolak | ✔ | ||

| AP 1201 E | PtBP Novolak | ✔ | ✔ | |

| AP 121 | PtOP Novolak | ✔ | ||

| AP 121 H | PtOP Novolak | ✔ | ||

| AP 130 | Mod.Phenol Novolak | ✔ | ||

| AP 131 | Mod.Phenol Novolak | ✔ | ||

| AP 132 | PF Novolak | ✔ | ||

| AP 1321 | PF Novolak | ✔ | ||

| AP 133 | Mod.Phenol Novolak | ✔ | ||

| PF 132 | PF Novolak | ✔ | ||

| PF 420 | PF Novolak | ✔ | ||

| PF 425 | PF Novolak | ✔ | ||

| PF 200 | 2 Part PF Novolak | ✔ | ||

| PF 201 | 2 Part PF Novolak | ✔ | ||

Octyl Phenol Basesd Tackifier for Rubber, Tyre, Adhesive

| Tackifier / Tackifying/insulating | ||

|---|---|---|

| POLYTONE® AP 121 | POLYTONE® AP 121H | |

| Chemical Classification | Pure Phenolic Resin (Novolak) | Pure Phenolic Resin (Novolak) |

| Type | Non Heat Reactive /Tackifying Thermoplastic | Non Heat Reactive /Tackifying Thermoplastic |

| Colour | Pale Yellow/Light Reddish Brown | Pale Yellow/Light Reddish Brown |

| Softening Point (Ball & Ring) | 85 – 95 °C | 92 – 104 °C |

| Acid Value | 42 mg KOH/ g resin (Max) | 42 mg KOH/ g resin (Max) |

| Free Phenol | 1% Max | 1% Max |

| Characteristics |

|

|

| Solubility | These are oil soluble phenolic resin. It has complete solubility in all vegetable oils, aromatics, ketones soluble in esters, ketones, aromatic and aliphatic chlorinated hydrocarbons. oil It has limited solubility in aliphatic Insoluble in alcohols. | |

| Benefits | Superior Green tack as compared to Hydrocarbon Resins. It acts as a plasticizer and hold the rubber until vulcanization Imparts high tack levels and provided interplay adhesion These can be used to increase the open time in solvent based polychloroprene adhesives without affecting other properties | |

| Application/Industry | Tyre /Tire Building, Conveyor Belts, Rubber Hose, Rubber Lining, Rubber Mats, Rubber Sheets, Reinforced Rubber, Fabric Lined Rubber, Rubber Adhesives. Weather resistant finishes, Spar Varnishes, Cold-Mix Varnishes | |

Butyl Phenol Basesd Tackifier for Rubber, Tyre, Adhesive

POLYTONE® AP 120 and AP 120 H are Butyl Phenol based Novolak Phenolic Tackifier. They are designed to provide a economical solution to formulators. Though their performance is lower compared to the Octyl Phenol based (POLYTONE® AP 121/121H) products, their cost effective ness makes them a competitive choice. They can be readily used to replace Hydrocarbon Resin in the formulation.

| Tackifier / Tackifying | ||

|---|---|---|

| POLYTONE® AP 120 | POLYTONE® AP 120H | |

| Chemical Classification | Butyl Phenol (PtBP) Formaldehyde Novolak Resin | Pure Phenolic Resin (Novolak) |

| Type | Non Heat Reactive /Tackifying Thermoplastic | Non Heat Reactive /Tackifying Thermoplastic |

| Colour | Pale Yellow/Light Reddish Brown | Pale Yellow/Light Reddish Brown |

| Colour Gardner (60% Soln in Xylene) | 8 Max | 8 Max |

| Softening Point (Ball & Ring) | 92 – 103 °C | 98 – 110 °C |

| Acid Value | 42 mg KOH/ g resin (Max) | 60 mg KOH/ g resin (Max) |

| Characteristics |

|

|

| Solubility | These are oil soluble phenolic resin. It has complete solubility in all vegetable oils, aromatics, ketones soluble in esters, ketones, aromatic and aliphatic chlorinated hydrocarbons. oil It has limited solubility in aliphatic Insoluble in alcohols. | |

| Benefits | Excellent compatibility in synthetic and natural rubbers. Blends easily into rubber stocks These shall provide resistance against weather, alkali, water and abrasion These can be used to increase the open time in solvent based polychloroprene adhesives without affecting other properties | |

| Application/Industry | Tyre /Tire Building, Conveyor Belts, Rubber Hose, Rubber Lining, Rubber Mats, Rubber Sheets, Reinforced Rubber, Fabric Lined Rubber, Rubber Adhesives. Weather resistant finishes, Spar Varnishes, Cold-Mix Varnishes | |

POLYTONE® AP 1201 E and AP 120 E are a non heat reactive thermoplastic phenolic resin with excellent alcohol solubility. It is quick drying, has excellent color retention and is resistant to weathering, alkalis, water and abrasion. It is designed to develop high tack levels in rubber compounds which are usedin tyre construction and mechanical goods. POLYTONE® AP 1201 E and AP 120 E finds its use in tung-oil based varnishes processed at 450°C. POLYTONE® AP 1201 E and AP 120 E will add surface harness to polyamide-based inks

| Tackifier / Tackifying/ Insulating | ||

|---|---|---|

| POLYTONE® AP 1201 E | POLYTONE® AP 120 E | |

| Chemical Classification | Pure Phenolic Resin (Novolak) | Pure Phenolic Resin (Novolak) |

| Type | Non Heat Reactive /Tackifying Thermoplastic | Non Heat Reactive /Tackifying Thermoplastic |

| Colour | Light Reddish Brown | Pale Yellow/Light Reddish Brown |

| Colour Gardner (60% Soln in Xylene) | 12 Max | 8 Max |

| Softening Point (Ball & Ring) | 135 – 145 °C | 150 – 165 °C |

| Acid Value | 100 mg KOH/ g resin (Max) | 100 mg KOH/ g resin (Max) |

| Characteristics |

|

|

| Solubility | These are oil soluble phenolic resin. It has complete solubility in all vegetable oils, aromatics, ketones soluble in esters, ketones, aromatic and aliphatic chlorinated hydrocarbons. oil It has limited solubility in aliphatic Insoluble in alcohols. | |

| Benefits | Excellent compatibility in synthetic and natural rubbers. Blends easily into rubber stocks These shall provide resistance against weather, alkali, water and abrasion These can be used to increase the open time in solvent based polychloroprene adhesives without affecting other properties | |

| Application/Industry | Tyre /Tire Building, Conveyor Belts, Rubber Hose, Rubber Lining, Rubber Mats, Rubber Sheets, Reinforced Rubber, Fabric Lined Rubber, Rubber Adhesives. Weather resistant finishes, Spar Varnishes, Cold-Mix Varnishes | |

Characteristics – Performance Vs Hydrocarbon Resins (For Octyl Phenol Based)

Effect on Formulation

| Product Name POLYTONE® | Building Tack Interply Adhesion | Chemical & Weather Resistance | Plasticizer Property | Economical |

|---|---|---|---|---|

| AP 120 | ★★★ | ★★★ | ★★★ | ★★★★ |

| AP 120 H | ★★★ | ★★★ | ★★★ | ★★★★ |

| AP 120 E | ★★ | ★★★★ | ★★ | ★★★ |

| AP 1201 E | ★★ | ★★★★★ | ★★ | ★★★ |

| AP 121 | ★★★★ | ★★ | ★★★★★ | ★★ |

| AP 121 H | ★★★ | ★★ | ★★★★ | ★★ |

| ★★★★★ : Excellent | ★★★★: Good | ★★★: Fair | ★★: Moderate | ★: Poor |

| SOLUBILITY | |

|---|---|

| POLYTONE®AP 120 POLYTONE®AP 121 |

|

| Alcohols | |

| Higher Alcohols | |

| Ketones | |

| Esters | |

| Aromatic Hydrocarbons | |

| Chlorinated Hydrocarbons | |

| Aliphatic Hydrocarbon | |

| Oil | |

|

Soluble Limited Solublility Insoluble |

|

| COMPATIBILITY | |

|---|---|

| POLYTONE®AP 120 POLYTONE®AP 121 |

|

| SBR | |

| SBR-BR Blends | |

| Butyl & Chlorobutyl | |

| Polyisoprene | |

| Neroprene | |

| NBR | |

| Polybutadiene | |

| Cis-Polybutadiene | |

|

Fully Compatible Limited Compatible Not Compatible |

|

Typical Uses

| Product Name POLYTONE® | Rubber & Tire | Adhesives/ Tacky Tapes | Wire Enamels & Varnish | Paints & Inks |

|---|---|---|---|---|

| AP 120 | ★★★★ | ★★★ | ★★ | ★★★★ |

| AP 120 H | ★★★★ | ★★ | ★★ | ★★★★ |

| AP 120 E | ★★★ | ★ | ★★★★★ | ★★★ |

| AP 1201 E | ★★★ | ★ | ★★★★★ | ★★★ |

| AP 121 | ★★★★★ | ★★★★ | ★ | ★★ |

| AP 121 H | ★★★★★ | ★★★★ | ★ | ★★ |

| ★★★★★: Excellent | ★★★★: Good | ★★★: Fair | ★★: Moderate | ★: Poor |

-

Tyre & Rubber: POLYTONE® AP 121/121H acts as excellent tackifiers and assists keeping the green rubber compound intact until cured. Due to the molecular property of the resin the tackifier quicky travels to the substrate on the compound providing the much needed building tack.

-

Rubber Goods: Tyre /Tire Building, Conveyor Belts, Rubber Hose, Rubber Lining, Rubber Mats, Rubber Sheets, Reinforced Rubber, Fabric Lined Rubber, Rubber Adhesives.

-

Plasticizer: These resins contribute as plasticizers during the compound of the rubber compound. POLYTONE® 120 acts as a relatively cheaper option compared to the POLYTONE® AP 121.

-

Rubber Adhesives: These tackifier resins provide a both initial tack, green tack along with long lasting tack which is essential in certain application.

-

Pressure Sensitive Adhesives: Due to the tacky nature of these product these resins are an ideal choice for pressure sensitive adhesives, tapes, tacky tapes and cellophane tapes.

-

Cable/Wire Enamels: High melting point resins like the POLYTONE® 120E/1201E are an ideal choice formulating high performance wire coating and enamels. Good compatibility with usual polyamide based coating provides the necessary di-electric properties needed in the coatings

-

Weather Resistant Coating: These resins provide good resistance to chemicals and weathering. Not only do they act as tackifier but they also contribute towards providing essential resistant properties.

-

Polyamide Based Inks: Addition of POLYTONE® 120E provides anti-freeze properties to polyamide based inks.

- Available in 25Kg HDPE Line KRAFT Paper Bags with Anti-Static Liner or 25Kg HDPE Bags

- Choice of ISPM 15 Standard Heat Treated/Fumigated Pallets or Plastic Pallets.

- Individual pallets must NOT be double stacked – pastilles/lumps are likely to agglutinate.

- Properties are not affected by agglutination.

- Phenolic Resins tend to discolor over time.

- Can be stored up to 12 months at temperatures below 35 °C.

Please follow advice and information provided in MSDS. Protective clothing & workplace hygiene measure must be observed at all times.

Detailed MSDS available on request.

Want to Know more!

Get in touch with our experts!!