POLYTONE®

Thermoplastic Acrylic

POLYTONE® ABR-Series

POLYTONE® ABR Series Acrylic Bead Resins are polymers or copolymers of acrylic monomers for use in solvent applied lacquers, inks, speciality coatings & adhesives. These resins are available in fine granules and are thermoplastic in nature; they are thermally stable upto 180-235C. Coatings of these resins give water white transparent films having gloss and hardness. POLYTONE® Acrylic Bead Resins provide excellent abrasion resistance & weatherability with low pigment reactivity. Having compatibility with a variety of plasticizers and file formers these resins provide excellent resistance to alkalies dilute acids, alcohols as also corrosive and oxidizing atmospheres. POLYTONE® Acrylic Bead Resins show outstanding resistance to ultraviolet degradation and resistance to discolouration on heating.

Thermoplastic Acrylic Resin

POLYTONE® ABR

Type

Thermoplastic

Acrylic Polymer

Solvent Soluble

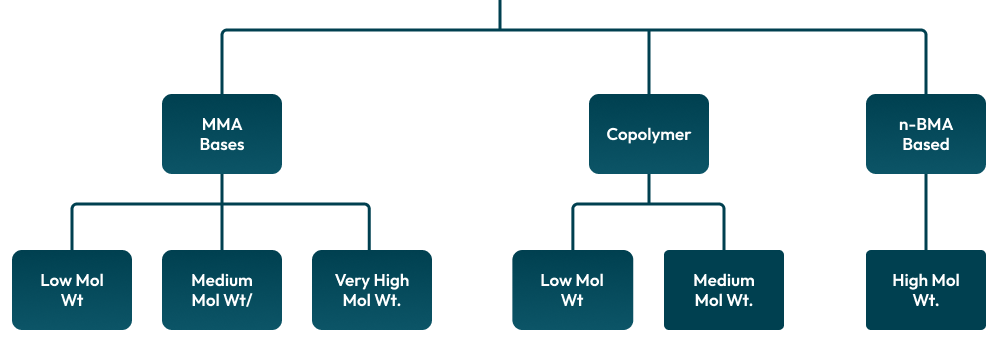

Chemistry: ABR 1011,1012,1013,1014

Suspension Polymer

MMA

Methyl Metharcylate

Chemistry: ABR 1033,1034

Co Polymer

Butyl Methacrylate - Methyl Methacrylate

MM - BMA

Chemistry: ABR 1044

n-BMA Based

Thermoplastic Acrylic Resin/ Homo-Polymer/MMA Based

| POLYTONE® ABR 1011 | POLYTONE® ABR 1012 | POLYTONE® ABR 1013 | POLYTONE® ABR 1014 | |

|---|---|---|---|---|

| Colour & Form | White Beads | White Beads | White Beads | White Beads |

| Glass Transition Temperature | 95 °C | 98 °C | 87 °C | 105 °C |

| Viscosity of 17.5% solution in Toluene at 25º C | 12 – 16 Poises | 8.5 – 10.5 Poises | ||

| Viscosity of 37.5% solution in Toluene at 25º C | 33 – 37 Poises | 16 – 18 Poises | ||

| Acid Value | 0 mg KOH/ g resin | 0 mg KOH/ g resin | 0 mg KOH/ g resin | 9 mg KOH/ g resin |

| Molecular Weight | Very High | Medium | Medium | Low |

| Characteristics |

|

|

|

|

| Application/Industry | Barrier Coating on Vinyl Fabric,Scuff Resistance Top Coats. | Lacquers, Clear Lacqures for Steel, Barrier Coatings | Lacquers, Clear Lacqures for Steel, Barrier Coatings | Base Coat for Vacuum Metalizing, Gravure Inks Low Viscosity |

Thermoplastic Acrylic Resin/ CO-POLYMER

| POLYTONE® ABR 1033 | POLYTONE® ABR 1034 | |

|---|---|---|

| Colour & Form | White Beads | White Beads |

| Glass Transition Temperature | 81 °C | 40 °C |

| Viscosity of 17.5% solution in Toluene at 25º C | 1 – 3 Poises | 4 – 6 Poises |

| Acid Value | 5.0 mg KOH/ g resin | 14.0 mg KOH/ g resin |

| Molecular Weight | Low | Medium |

| Characteristics |

|

|

| Application/ Industry | Industrial Lacquers, Flexo and Gravure Inks, Aerosol Sprays, Toners | Clear Metal Lacquers, Mettalic Paints & Inks |

Thermoplastic Acrylic Resin/ N-BMA Based

| POLYTONE® ABR 1044 | |

|---|---|

| Colour | White |

| Glass Transition Temperature | 17 ° C |

| Viscosity of 30% solution in Toluene at 25º C | 1 – 2.5 Poises |

| Acid Value | 0 mg KOH/ g resin |

| Molecular Weight | High |

| Characteristics |

|

| Application/ Industry | Cigratte Packaging, Adhesives, |

Compatibility

The compatibility of POLYTONE® Acrylic resins with a variety of plasticizers and reins help in the formulation of adhesives, lacquers, inks etc.

Alkyd Resins : In general alkyds as a class have poor compatibility with acrylic. Acrylic modified alkyds show better compatibility. Copolymers resins e.g ABR 1033 and 1035 can be combined with a suitable alkyd for gloss and improved pigment wetting.

Vinyl Chloride Resins : Have excellent compatibility with POLYTONE® Acrylic resins. Vinyl chloride homopolymers also compatible. By blending these resins excellent abrasion resistance, gloss retention and slip are achieved.

Chlorinated Rubber : is compatible with most grades of POLYTONE® Acrylic resins. Aromatic rich solvents should be first used for optimum compatibility.

Cellulosics : Nitrocellulose and cellulose actate bytyrate are compatible with POLYTONE® Resins. Inclusion of cellulosics increases the block resistance and hardness of soft Polytone resins like 1034, 1035, 1044. On the other hand softer acrylics can be helpful for improving the flexibility and durability of the cellulosics. Other Resins such as epoxy, ketone, rosin esters, amino, cumarone-indone are compatible with POLYTONE® resins. ABR 1034, 1035 can be used as modifiers and extenders for silicone resins.

Plasticizers : POLYTONE® acrylic resins are compaltible with a number of plasticizers. Pthalate esters in general are useful plasticizers for POLYTONE® Resins.

Solubility

| POLYTONE® ABR Series | |

|---|---|

| Colour | White |

| Aromatic Hydrocarbon - Toluene - Xylene |

|

| Ethers | |

| Alcohols -Methanol -Ethanol |

|

| Higher Alcohols -N-Butanol -ISO-Butanol |

|

| Esters | |

| Ketones -Cyclohexanone -Methyl Ethyl Ketone -Methyl Iso Butyl Ketone |

|

| Nitro Parrafins | |

| Acetonitrile | |

| Mineral Oils | |

| Long Castor Oil | |

| Water | |

|

Fully Compatible Limited Compatible Not Compatible |

|

Compatibility (Parts By Weight)

| POLYTONE® ABR Series | |

|---|---|

| Nitrocellulose | |

| Epoxy Resin | |

| Silicones | |

| Cummarone Indene Resins | |

| PTSF Resins | |

| Vinyl Chloride | |

| CAB Resin | |

| Chlorinated Rubber | |

| Maleic Resin | |

| Alkyd Resin | |

|

Fully Compatible Limited Compatibility Not Compatible |

|

Application/Compatibility

| 1011 | 1012 | 1013 | 1014 | 1033 | 1034 | 1044 | |

|---|---|---|---|---|---|---|---|

| Flexographic Inks | ✔ | ✔ | ✔ | ||||

| Gravure Inks | ✔ | ✔ | ✔ | ✔ | |||

| Overprint | ✔ | ✔ | |||||

| Silk Screen | ✔ | ✔ | ✔ | ||||

| Polystrere/ABS | ✔ | ✔ | ✔ | ||||

| Vinyl | ✔ | ✔ | ✔ | ||||

| Steel | ✔ | ✔ | ✔ | ✔ | |||

| Metal | ✔ | ||||||

| Mansonry | ✔ | ✔ | |||||

| Marine | ✔ | ✔ | |||||

| Automotive Finish | ✔ | ✔ | ✔ | ✔ | |||

| Automotive Finish | ✔ | ✔ | |||||

| Zinc Oxide Binders | ✔ | ✔ | |||||

| Adhesive | ✔ | ||||||

| Aerosol | ✔ | ✔ |

| Grade | MOL. WT. | Principal Characteristics & Uses |

|---|---|---|

| ABR 1011 | V. High | Used in Barrier Coating on vinyl fabrics for difference for dielectric heat sealibility, high abrasion resistance, block resistance and slip. Since this resin provides maximum toughness and abrasion resistance, it is suggested as scuff resistance top coat for luggage and similar items. |

| ABR 1012 | Medium | General purpose grade for lacquers such as barrier top coating of vinyl fabrics , clear lacquer for steel, ABS , Polystyrene etc. Suitable for gravure inks. Very high tensile strength and hardness. |

| ABR 1013 | Medium | This resin is a softer version of ABR 1012 having the same uses. Excellent chip resistance. |

| ABR 1014 | Low | Lowest Molecular Weight Grade. Used in lacquers and gravure inks requiring low viscosity at high solids . High Tack Temperature. Good Pigment Dispersion. Used in Base coat for Vacuum Metalizing of Plastic Articles. |

| ABR 1033 | Low | Fast dissolving low viscosity Grade with quick solvent release properties for use in industrial lacquers, flexo and gravure inks, coatings for plastics-polyester, ABS, toners, aerosol sprays. |

| ABR 1034 | Medium | Softest and the most flexible grade having good pigment wetting properties. Useful for clear. translucent or pigmented metal lacquers for aluminium, bronze, steel and bright metals like silver, copper, brass. Also used in electrofax copy paper and seamless flooring. |

| ABR 1044 | High | Very soft flexible grade. Useful in adhesives for smooth plastic films and aluminIum. Used in silk screen inks. Can be used for plasticizing and improving adhesion of harder resins and nitrocellulose. Improves outdoor durability of vinyl chloride in pigmented lacquers. |

- Available in 20/25Kg HDPE Line KRAFT Paper Bags with Anti-Static Liner or 20/25Kg HDPE Bags

- Choice of ISPM 15 Standard Heat Treated/Fumigated Pallets or Plastic Pallets.

- 500Kg/1000Kg Jumbo Bags available as an option

- Can be stored up to 12 months at temperatures below 35 °C.

Please follow advice and information provided in MSDS. Protective clothing & workplace hygiene measure must be observed at all times.

Detailed MSDS available on request.

Want to Know more!

Get in touch with our experts!!