POLYTONE®

Alkyl Phenol Heat Reactive Resins

About Polytone AP Series - Adhesive Resin

With more than 30 Grades in POLYTONE® AP Series, we offer resins to a wide spectrum of Industries like Rubber Adhesives, Shoe Adhesives, Upholstery Adhesives, Automotive Adhesives, Paints, Varnishes and Lacquers, Tyre/Tire Building, Conveyor Belting, Shoe soles, Tire Beads and many more.

POLYTONE® AP Series Phenolic Resin are oil-soluble, heat-reactive phenolic resin developed for formlulating non-phasing polychloroprene solvent-type contact adhesives.

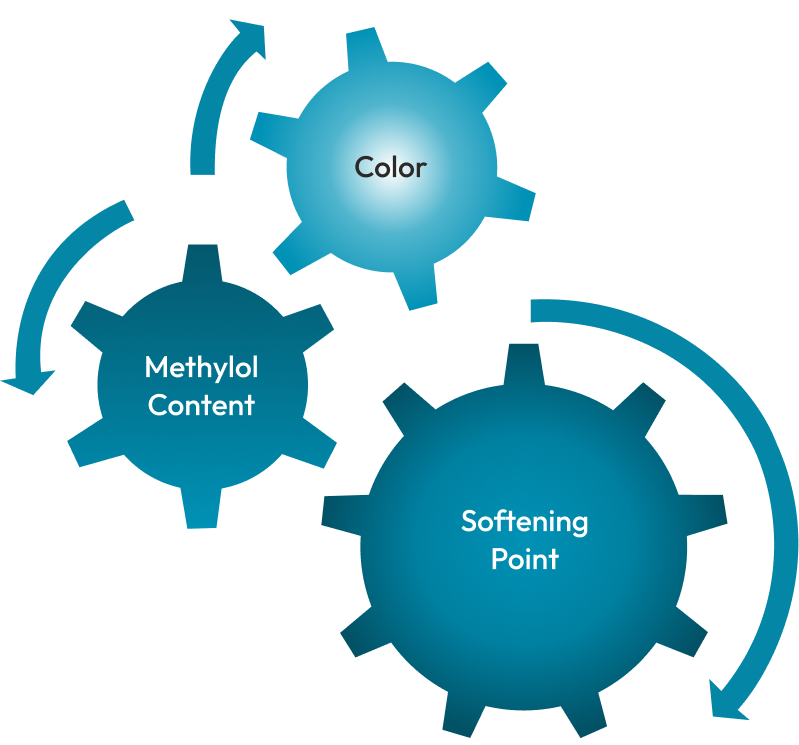

Wide range of these resins impart properties like high heat resistance, cohesive strenght, long or short open time/green Time, high or low Tack, quick or slow drying.

Added feature of colour choices – Light Yellow, Amber, Honey and Dark Violet increases potential product variations. Incorporation of these resins in polycholoroprene adhesive formulation porvides excellent static and dynamic strength properties.

The premium grade synthetic resin offered by us has received wide acceptance all across the world, especially in European markets, Northeast African countries, South African countries, Southeastern Asia and South America. About 75% of our entire products range and more than 95% of our POLYTONE® AP Series Alkyl Phenol Resins are exported, majorly to European countries.

We are a trusted name and offer only quality range of synthetic resin to our clients. Owing to our professional approach, quality products and services, we have become the most preferred choice of our clients.

Type

Heat Reactive/Reactive

Thermosetting

Chemistry

Alkylphenol Formaldehye

PtBP Formaldehye

PtBP Resin

Tert Butyl Phenol

Toluene Free

Phenolic Resin Type

Resol

Resole

Speciality Grades/Heat Resistant Grades

| POLYTONE® AP 108 | POLYTONE® AP 109 | POLYTONE® AP 110 | POLYTONE® PHR 105 | |

|---|---|---|---|---|

| Chemical Classification | Butyl Phenol (PtBP) Formaldehyde Resol Resin | |||

| Colour | Pale Yellow | Pale Yellow/ Honey Color(109D) | Pale Yellow | Amber Light Yellow Transparent Solid |

| Softening Point (Ball & Ring) | 110°C - 125 °C | 95°C-110 °C | 110°C - 120 °C | 100° C - 105 °C |

| Melting Point (Capillary) | 75°C-90 °C | - | - | |

| Viscosity (B4 Ford Cup @ 30°C) | 80°C - 130 Sec (60% Soln in Toluene) | 35 - 70 Sec (60% Soln in Toluene) | 35 - 75 Sec (60% Soln in Toluene) | |

| Methylol Content | 8 - 13% | 10 - 14% | 10 - 14% | 10-13 % |

| Moisture Content | ≤ 0.5% | ≤ 0.5% | ≤ 0.5% | ≤ 0.5% |

| Characteristics |

|

|

|

|

High Bond Strength/High Methylol Grades

| POLYTONE® AP 111 | POLYTONE® AP 111 HM | POLYTONE® AP 110 HM | POLYTONE® PHR 150 | |

|---|---|---|---|---|

| Chemical Classifiction | Butyl Phenol (PtBP) Formaldehyde Resol Resin | |||

| Colour | Pale Yellow | Amber Light Yellow Transparent Solid | Pale Yellow | Amber Light Yellow Transparent Solid |

| Softening Point (Ball & Ring) | 92° C - 100 °C | 92° C - 102 °C | ||

| Melting Point (Capillary) | 70° C - 80 °C | 70° C - 80 °C | 90° C - 95 °C | |

| Methylol Content | 14-18 % | 16-18 % | 14-18 % | 16-18 % |

| Moisture Content | 0.5% Max | ≤ 0.5% | 0.5% Max | ≤ 0.5% |

| Characteristics |

|

|||

General Purpose And High Tack Grades

| POLYTONE® AP 112 | POLYTONE® 112 H | POLYTONE® PHR 90 | POLYTONE® PHR 100L | |

|---|---|---|---|---|

| Chemical Classifiction | Butyl Phenol (PtBP) Formaldehyde Resol Resin | |||

| Colour | Pale Yellow | Pale Yellow | Amber Light Yellow Transparent Solid | Amber Light Yellow Transparent Solid |

| Softening Point (Ball & Ring) | 83°C - 95 °C | 90° C - 110 °C | 85° C - 105 °C | 100° C - 105 °C |

| Melting Point (Capillary) | 60 °C - 70 °C | |||

| Methylol Content | 10 - 13% | 10-13 % | 10-12 % | 08-10 % |

| Moisture Content | ≤ 0.5 % | 0.5% Max | ≤ 0.5% | ≤ 0.5% |

| Characteristics |

|

|||

Colored Grades

| POLYTONE® AP 109 D | POLYTONE® AP 114 | POLYTONE® PHR 115 | ||

|---|---|---|---|---|

| Chemical Classifiction | Butyl Phenol (PtBP) Formaldehyde Resol Resin | |||

| Colour | Honey Colour/Reddish | Dark Violet | Dark Violet | |

| Softening Point (Ball & Ring) | 95° C-110 °C | 88° C-102 °C | ||

| Melting Point (Capillary) | 70° C-80 °C | 60° C-70 °C | ||

| Methylol Content | 10-14% | 12-17% | 10-13% | |

| Moisture Content | 0.5% Max | 0.5% Max | 0.5% Max | |

| Characteristics |

|

|||

Toluene Free Grades

| POLYTONE® AP 112 XD | POLYTONE® AP 109 XD | POLYTONE® AP 110 XD | ||

|---|---|---|---|---|

| Chemical Classifiction | Butyl Phenol (PtBP) Formaldehyde Resol Resin | |||

| Colour | Pale Yellow | Pale Yellow | Pale Yellow | |

| Softening Point (Ball & Ring) | 83-95 °C | 95°C-110 °C | 110° C-120 °C | |

| Melting Point (Capillary) | 60-70 °C | |||

| Methylol Content | 10-13% | 10-14% | 10-14% | |

| Moisture Content | ≤ 0.5% | 0.5% Max | 0.5% Max | |

| Characteristics |

|

|||

| Heat Resistance | |

|---|---|

|

|

| Open Time/ Tick Time/ Green Time | |

|---|---|

|

|

-

Shoe, Automotive, Aircraft, Furniture, Building & others: Application available are broad, apart from usual polychloroprene adhesive, application areas include shoe, automotive, aircraft, furniture, building. Added feature of high heat resistance, high cohesive strength and color options further increases the number of potential uses.

-

With Rubber Stock: It can be used as base resin and also as modifying resin. Can be mixed directly into solvent to make a solution or can be milled with rubber stock.

-

Varnishes, Insulation coatings, Printing inks: Because of its reactivity, adhesion properties and heat resistant it has also found application in varnishes, insulation coatings, printing inks.

-

Hard Ink Resins and Coating: Can be used in formulation of hard ink resins and coating with chemical resistance.

-

Deck and Floor: In formulation of medium & long oil exterior and interior varnishes and spar varnishes for deck and floor.

- Available in 25Kg HDPE Line KRAFT Paper Bags with Anti Static Liner or 25Kg HDPE Bags.

- Choice of ISPM 15 Standard Heat Treated/Fumigated Pallets or Plastic Pallets.

- Individual pallets must NOT be double stacked – pastilles/lumps are likely to agglutinate.

- Properties are not affected by agglutination.

- Can be stored up to 12 months at temperatures below 35 °C.

Please follow advice and information provided in MSDS. Protective clothing & workplace hygiene measure must be observed at all times.

Detailed MSDS available on request.

Want to Know more!

Get in touch with our experts!!