POLYTONE®

Phenolic Resin -Reinforcing

About Polytone® AP Series Reinforcing

POLYTONE® AP Reinforcing Resins are usually used in conjugation with methylene donor like Hexa. Most wide use in in the apex of tires or in rubber compounds which require hardness. POLYTONE® AP 130/131/133 are manufactured using modified phenols to provide required property.

POLYTONE® AP 131 is particularly suited for industrial tread Applications such as farm, off the road, mining and truck tires. Tread compounds with 5-10 PHR of AP 131 cross linked with a methylene donor shall have excellent cut and chip resistance along with excellent abrasion resistance and high hardness.

POLYTONE® Resins which are on unmodified phenols provides higher hardness compared to other products. They are designed to give a consistent performance as a reinforcing resin in synthetic and natural rubber-based goods that require high hardness, excellent chip and abrasion resistance when cross linked with a methylene donor. There are used as a reinforcing resin in tire beads, shoe soles, apex strips and co-extruded window profiles.

POLYTONE® PF 132 can be used as an epoxy-phenolic co reactant in wide range of epoxy co reactant applications like laminates, adhesives and coatings. POLYTONE® PF 132 can also be used in varnishes, insulations, inks and coatings.

POLYTONE® PF 425 and POLYTONE® PF 420 are Non Heat Reactive/Thermoplastic Phenol –Formaldehyde Novolak Resins POLYTONE® PF 420 is a high purity Non Heat Reactive/Thermoplastic Phenol – Formaldehyde Novolak Resin with low softening point.

Type

Non Heat Reactive

Thermoplastic

Reinforcing

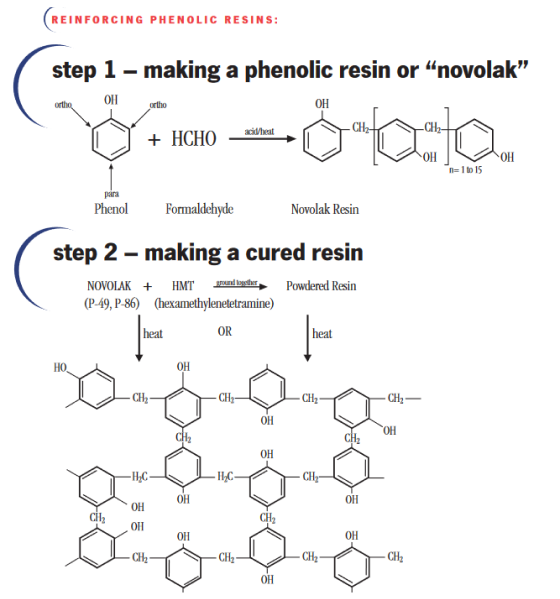

Chemistry : POLYTONE® AP 130

Alkyl Phenol Formaldehyde

PtBP Resin/Butyl Phenol

Para Tert Butyl Phenol Resin

Chemistry : POLYTONE® AP 131

Alkyl Phenol Formaldehye

Phenol-POP Resin

Phenol-Octyl Phenol

Chemistry: POLYTONE® AP 132/ 1321/PF 132/PF 420/PF 425

Phenol Formaldehdye

Unmodified Phenolic Novolak

Phenolic Resin Type

Novolak

| POLYTONE® | Butyl Curing | Tackifier | Reinforcement | |

|---|---|---|---|---|

| AP 113 | PtOP Resol | ✔ | ||

| AP 113 A | PtOP Resol | ✔ | ||

| AP 120 | PtBP Novolak | ✔ | ||

| AP 120 H | PtBP Novolak | ✔ | ||

| AP 120 E | PtBP Novolak | ✔ | ||

| AP 1201 E | PtBP Novolak | ✔ | ✔ | |

| AP 121 | PtBP Novolak | ✔ | ||

| AP 121 H | PtBP Novolak | ✔ | ||

| AP 130 | Mod.Phenol Novolak | ✔ | ||

| AP 131 | Mod.Phenol Novolak | ✔ | ||

| AP 132 | PF Novolak | ✔ | ||

| AP 1321 | PF Novolak | ✔ | ||

| AP 133 | Mod.Phenol Novolak | ✔ | ||

| PF 132 | PF Novolak | ✔ | ||

| PF 420 | PF Novolak | ✔ | ||

| PF 425 | PF Novolak | ✔ | ||

| PF 200 | 2 Part PF Novolak | ✔ | ||

| PF 201 | 2 Part PF Novolak | ✔ |

Properties

| Product Name POLYTONE® | Thermoplastic | Methylene Donor Required | Alkyl Phenol Based | Pure Phenol Based |

|---|---|---|---|---|

| AP 130 | ✔ | ✔ | ✔ | |

| AP 131 | ✔ | ✔ | ✔ | |

| AP 132 | ✔ | ✔ | ✔ | |

| AP 1321 | ✔ | ✔ | ✔ | |

| AP 133 | ✔ | ✔ | ✔ | |

| PF 132 | ✔ | ✔ | ✔ | |

| PF 420/425 | ✔ | ✔ | ✔ | |

| PF 200/201 | 2 Component | ✔ + Catalyst |

Reinforcing Resins – Modified Phenol Based

POLYTONE® AP Reinforcing Resins are usually used in conjugation with methylene donor like Hexa. Most wide use in in the apex of tires or in rubber compounds which require hardness.

POLYTONE® AP 130/131/133 are manufactured using modified phenols to provide required property.

POLYTONE® AP 131 is particularly suited for industrial tread Applications such as farm, off the road, mining and truck tires. Tread compounds with 5-10 PHR of AP 131 cross linked with a methylene donor shall have excellent cut and chip resistance along with excellent abrasion resistance and high hardness.

Rubber Reinforcing

| POLYTONE® AP 130 | POLYTONE® AP 131 | POLYTONE® AP 133 | |

|---|---|---|---|

| Chemical Classification | Butyl Phenol (PtBP) Formaldehyde Novolak Resin | Phenol – Octyl Phenol (PtOP) Formaldehyde Novolak Resin | Phenol -Butyl Phenol (PtBP) Formaldehyde Novolak Resin |

| Type | Non Heat Reactive /Thermoplastic | Non Heat Reactive /Thermoplastic | Non Heat Reactive /Thermoplastic |

| Colour | Pale Yellow/light Reddish Brown | Pale Yellow/light Reddish Brown | Pale Amber |

| Softening Point (Ball & Ring) | 90 – 103 °C | 90 – 105 °C | 100 – 110 °C |

| Methylol Content | - | 1.0% Max | - |

| Acid Value | 45 mg KOH/ g resin (Max) | 45 mg KOH/ g resin (Max) | 45 mg KOH/ g resin (Max) |

| Free Phenol | 1.0% Max | 1.0% Max | 0.50% Max |

| Ash Content | 1.0% Max | 1.0% Max | 0.02% Max [@850°C] |

| Characteristics |

|

||

| Solubility | Soluble in esters, ketones, aromatic and aliphatic chlorinated hydrocarbons. Insoluble in higehr alcohols | ||

| Application/Industry | Used as a reinforcing resin in tire beads, shoe soles, apex strips and co-extruded window profiles. Tyre /Tire Building, Conveyor Belts, Rubber Hose, Rubber Lining, Shoe Soles, Apex Strips, Tire Beads, Tire Treads, Rubber Mats, Rubber Sheets, Reinforced Rubber, Fabric Lined Rubber, Rubber Adhesives, Rubber Goods and many more. |

||

Reinforcing Resins – Pure/Unmodified Phenol Based

POLYTONE® Resins which are on unmodified phenols provides higher hardness compared to other products They are designed to give a consistent performance as a reinforcing resin in synthetic and natural rubber based goods that require high hardness, excellent chip and abrasion resistance when cross linked with a methylene donor. There are used as a reinforcing resin in tire beads, shoe soles, apex strips and co-extruded window profiles .

POLYTONE® PF 132 can be used as an epoxy-phenolic co reactant in wide range of epoxy co reactant applications like laminates, adhesives and coatings .

POLYTONE® PF 132 can also be used in varnishes, insulations, inks and coatings.

POLYTONE® PF 425 and POLYTONE® PF 420 are Non Heat Reactive/Thermoplastic Phenol –Formaldehyde Novolak Resins

POLYTONE® PF 420 is a high purity Non Heat Reactive/Thermoplastic Phenol – Formaldehyde Novolak Resin with low softening point.

Rubber Reinforcing/Epoxy CO Reactant

| POLYTONE® AP 132 | POLYTONE® AP 1321 | POLYTONE® PF 132 | |

|---|---|---|---|

| Chemical Classification | Phenol Formaldehyde Resin (Novolak) | Phenol Formaldehyde Resin (Novolak) | Phenol Formaldehyde Resin (Novolak) |

| Type | Non Heat Reactive /Thermoplastic | Non Heat Reactive /Thermoplastic | Non Heat Reactive /Thermoplastic |

| Colour | Pale Yellow/light Reddish Brown | Pale Yellow/light Reddish Brown | Pale Yellow/light Reddish Brown |

| Softening Point (Ball & Ring) | 110 – 116 °C | 90 – 100 °C | 100 – 116 °C |

| Methylol Content | - | 1.0% Max | - |

| Free Phenol | 1.0% Max | 1.0% Max | 0.50% Max |

| Ash Content | 1.0% Max | 1.0% Max | 0.02% Max [@850°C] |

| Characteristics |

|

||

| Solubility | Soluble in esters, ketones, aromatic and aliphatic chlorinated hydrocarbons. Insoluble in higehr alcohols | ||

| Application/Industry | Used as a reinforcing resin in tire beads, shoe soles, apex strips and co-extruded window profiles. Tyre /Tire Building, Conveyor Belts, Rubber Hose, Rubber Lining, Shoe Soles, Apex Strips, Tire Beads, Tire Treads, Rubber Mats, Rubber Sheets, Reinforced Rubber, Fabric Lined Rubber, Rubber Adhesives, Rubber Goods and many more. Can be used as an epoxy-phenolic co reactant in wide range of epoxy co reactant applications like laminates, adhesives and coatings Can also be used in varnishes, insulations, inks and coatings |

||

Reinforcing/Epoxy CO Reactant

| POLYTONE® PF 425 | POLYTONE® PF 420 | ||

|---|---|---|---|

| Chemical Classification | Phenol Formaldehyde Resin (Novolak) | Phenol Formaldehyde Resin (Novolak) | |

| Type | Non Heat Reactive /Thermoplastic | Non Heat Reactive /Thermoplastic | |

| Colour | Pale Yellow/Light Reddish Brown | Pale Yellow/Light Reddish Brown | |

| Softening Point (Ball & Ring) | 110 – 120 °C | 80 – 90 °C | |

| Free Phenol | 5% | 2% | |

| Characteristics |

|

||

| Solubility | POLYTONE® PF 425/420 is soluble in alcohols, esters, ketones, aromatic and aliphatic chlorinated hydrocarbons. | ||

| Application/Industry | Tyre /Tire Building, Conveyor Belts, Rubber Hose, Rubber Lining, Rubber Mats, Rubber Sheets, Reinforced Rubber, Fabric Lined Rubber, Rubber Adhesives. POLYTONE® PF 425 and POLYTONE® PF 420 can be used as an epoxy-phenolic co reactant in wide range of epoxy co-reactant applications like laminates, adhesives and coatings POLYTONE® PF 425 and POLYTONE® PF 420 can also be used in varnishes and inks |

||

Reinforcing Resins – 2 Component/ Methylene Donor Based

| POLYTONE® PF 200 | POLYTONE® PF 201 | |

|---|---|---|

| Chemical Classification | Phenol Formaldehyde Resin with Hexa | Phenol Formaldehyde Resin with Hexa |

| Type | Heat Reactive/2 Step mixed with Hexa | Heat Reactive/2 Step mixed with Hexa |

| Colour | Cremish Yellow | Cremish Yellow |

| Melting Point (Capillary) | 75° C – 90 ° C | 70° C – 85 ° C |

| Inclined Plate Flow @ 125° C | 30 – 35mm | 30 – 45mm |

| Hot Plate Cure @ 150° C | 75 – 100 seconds | 40 – 65 seconds |

| Sieve Analysis (200 Mesh) | 90 - 95% Min | 96 – 99% Min |

| Hexa Content | 9 – 10 % | 7.5 – 8.5 % |

| Characteristics |

|

|

| Solubility | POLYTONE® PF 200/201 is soluble in alcohols, esters, ketones, aromatic and aliphatic chlorinated hydrocarbons. | |

| Application/Industry | Tires and technical rubber goods use straight phenolic novolac resins as reinforcing agents. Abrasives, Emry Wheels, Composites, Refractory, Cured phenolic resins demonstrate exceptional chemical resistance as coatings |

|

Effect on Formulation

| Product Name POLYTONE® | Hardness & Chip Resistance | Suitability for Tire Beads & Treds | Reinforcing | Processing Temperature |

|---|---|---|---|---|

| AP 130 | ★★★ | ★★★ | ★★★★ | ★★★★ |

| AP 131 | ★★★ | ★★★ | ★★★★ | ★★★★ |

| AP 132 | ★★★★★ | ★★★★★ | ★★★★★ | ★★★ |

| AP 1321 | ★★★★★ | ★★★★★ | ★★★★★ | ★★★ |

| AP 133 | ★★★ | ★★★★ | ★★★ | ★★★ |

| PF 132 | ★★★★★ | ★★★★★ | ★★★★★ | ★★★ |

| PF 420/425 | ★★★★ | ★★ | ★★★★ | ★★★★ |

- These resin in presence of catalyst become “Thermoset”.

- They provide “plasticizing effect” while processing.

- They increase “Shore Hardness” of Rubber Compound.

- They provide Hardness, Chip Resistance, Abrasion Resistance.

Solubility

| POLYTONE® PF Series | POLYTONE® PF Series | |

|---|---|---|

| Alcohols | ||

| Higher Alcohols | ||

| Ketones | ||

| Esters | ||

| Aromatic Hydrocarbons | ||

| Chlorinated Hydrocarbons | ||

| Aliphatic Hydrocarbon | ||

| Oil | ||

|

Soluble Limited Solublility Insoluble |

||

Compatibility

| POLYTONE® PF Series | |

|---|---|

| SBR | |

| SBR-BR Blends | |

| Natural Rubber | |

| Nitrile Rubber | |

|

Fully Compatible Limited Compatibility Not Compatible |

|

Typical Uses

| Product Name POLYTONE® | Rubber & Tire | Epoxy CO Reactant | Abrasives & Emery | Paints & Inks |

|---|---|---|---|---|

| AP 130 | ★★★★ | - | - | ★★★ |

| AP 131 | ★★★★ | - | - | ★★★ |

| AP 132 | ★★★★★ | ★★ | ★★ | ★★★★ |

| AP 1321 | ★★★★★ | ★★ | ★★ | ★★★★ |

| AP 133 | ★★★★★ | - | - | ★ |

| PF 132 | ★★★★★ | ★★★★★ | ★★ | ★★★ |

| PF 420/425 | ★★ | ★★★★★ | ★★ | ★★★ |

| PF 200/201 | ★★★★ | - | ★★★★★ | - |

| ★★★★★ :Excellent | ★★★★: Good | ★★★:Fair | ★★: Moderate | ★: Poor |

- Available in 25Kg HDPE Line KRAFT Paper Bags with Anti-Static Liner or 25Kg HDPE Bags

- Choice of ISPM 15 Standard Heat Treated/Fumigated Pallets or Plastic Pallets.

- Individual pallets must NOT be double stacked – pastilles/lumps are likely to agglutinate.

- Properties are not affected by agglutination.

- Phenolic Resins tend to discolor over time.

- Can be stored up to 12 months at temperatures below 35 °C.

Please follow advice and information provided in MSDS. Protective clothing & workplace hygiene measure must be observed at all times.

Detailed MSDS available on request.

Want to Know more!

Get in touch with our experts!!